Sheet Metal Stretching - These processes are based on the compression. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. Shrinking and stretching are fundamental techniques in the world of sheet metal working.

Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. These processes are based on the compression. Shrinking and stretching are fundamental techniques in the world of sheet metal working. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads.

Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. Shrinking and stretching are fundamental techniques in the world of sheet metal working. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. These processes are based on the compression.

Sheet Metal Fabrication A Brief Guide by Topgrid Topgrid

Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. Shrinking and stretching are fundamental techniques in the world of sheet metal working. These processes are based on the compression. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against.

1000 tons hydraulic press metal stamping and stretching hydraulic press

Shrinking and stretching are fundamental techniques in the world of sheet metal working. These processes are based on the compression. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against.

Marchant 4H Sheet Metal Shrinking and Stretching Machine

Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. Shrinking and stretching are fundamental techniques in the world of sheet metal working. These processes are based on the compression. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since.

Sheet Metal Stretch Forming for Aerospace Worldwide Service

These processes are based on the compression. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. Shrinking and stretching are fundamental techniques in the world of sheet.

MetalAce Stand, Lancaster Shrinker Stretcher Unit, Metal Shaping

Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. These processes are based on the compression. Shrinking and stretching are fundamental techniques in the world of sheet.

How To Make Tools To Stretch Sheet Metal YouTube

Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. Shrinking and stretching are fundamental techniques in the world of sheet metal working. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. These processes are based on.

Sheet Metal Stretching A Comprehensive Guide

Shrinking and stretching are fundamental techniques in the world of sheet metal working. These processes are based on the compression. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since.

Sheet Metal Stretch Forming for Aerospace Worldwide Service

Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. These processes are based on the compression. Shrinking and stretching are fundamental techniques in the world of sheet metal working. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against.

Metal Shaping with Lazze Stretching Aluminum in a Bead Roller YouTube

Shrinking and stretching are fundamental techniques in the world of sheet metal working. These processes are based on the compression. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since.

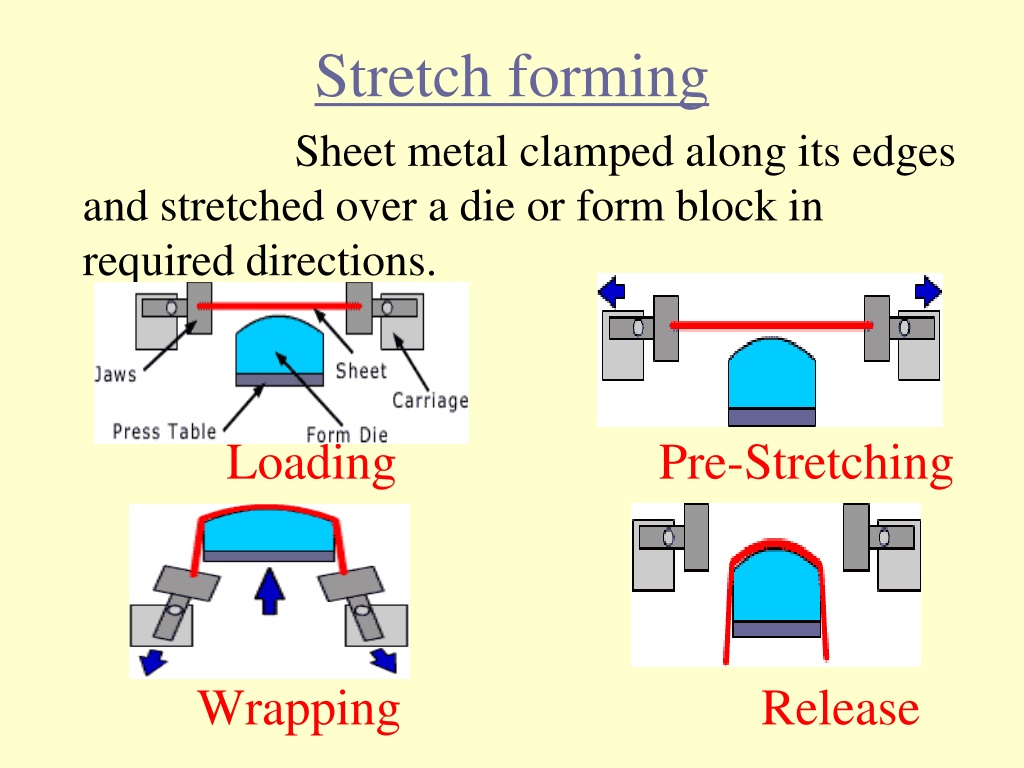

PPT SHEET METAL OPERATIONS PowerPoint Presentation, free download

Shrinking and stretching are fundamental techniques in the world of sheet metal working. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,. Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. These processes are based on.

Shrinking And Stretching Are Fundamental Techniques In The World Of Sheet Metal Working.

Stretching is the sheet metal forming process where the punch which creates the part shape forces the sheet metal to thin since lock beads. These processes are based on the compression. Reinforcement techniques such as bending, stretching, and adding ribs are employed to fortify the metal against such deformations,.