Sheet Metal Roll Forming - The forming on a roll former occurs as the sheet metal rolls under. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications. Any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Unlike most forming operations, which have various combinations of forming.

Unlike most forming operations, which have various combinations of forming. The forming on a roll former occurs as the sheet metal rolls under. Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications. Any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation.

Any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. The forming on a roll former occurs as the sheet metal rolls under. Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Unlike most forming operations, which have various combinations of forming.

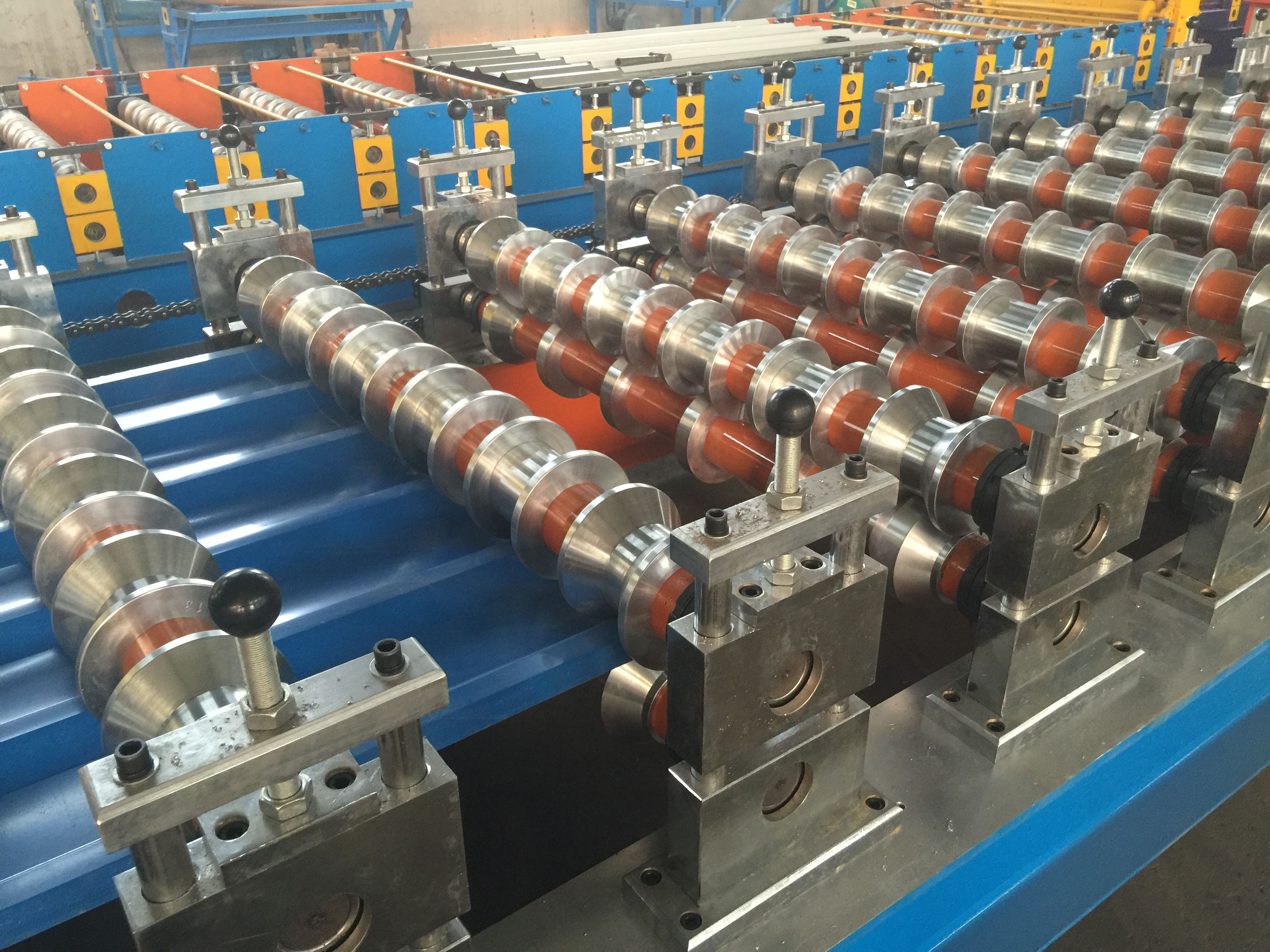

Sheet metal roll forming machines

Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. The forming on a roll former occurs as the sheet metal rolls under. Unlike most forming operations, which have various combinations of forming. Any time the sheet metal is changed on a roll forming line, it is carried out by the roll.

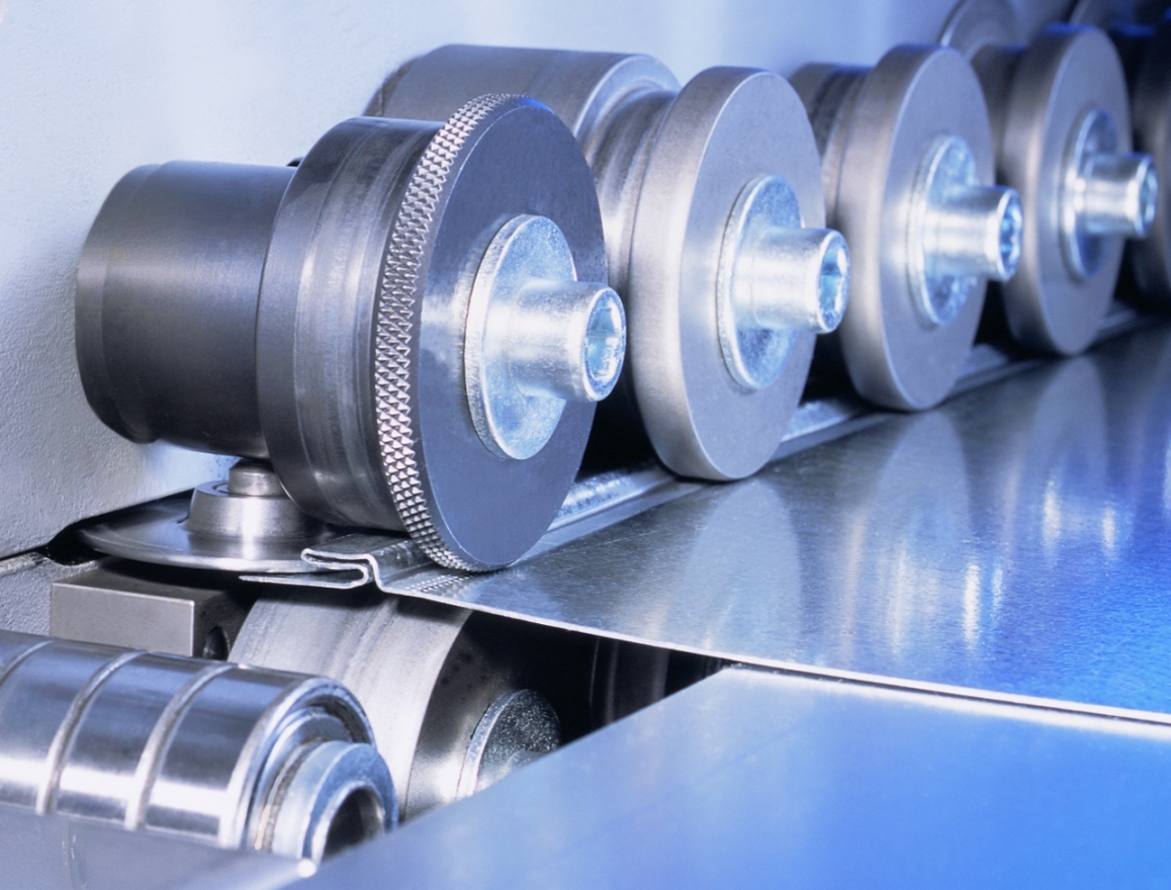

Custom Roll Forming Roll Formed Steel The Chicago Curve

Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Unlike most forming operations, which have various combinations of forming. Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed.

Roll Forming Metal Components Standard & Custom Roll Forming

Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications. Any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Unlike most.

Sheet Metal Roll Forming Roll Forming The Ultimate Guide 2021

Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Unlike most forming operations, which have various combinations of forming. The forming on a roll former occurs as the sheet metal.

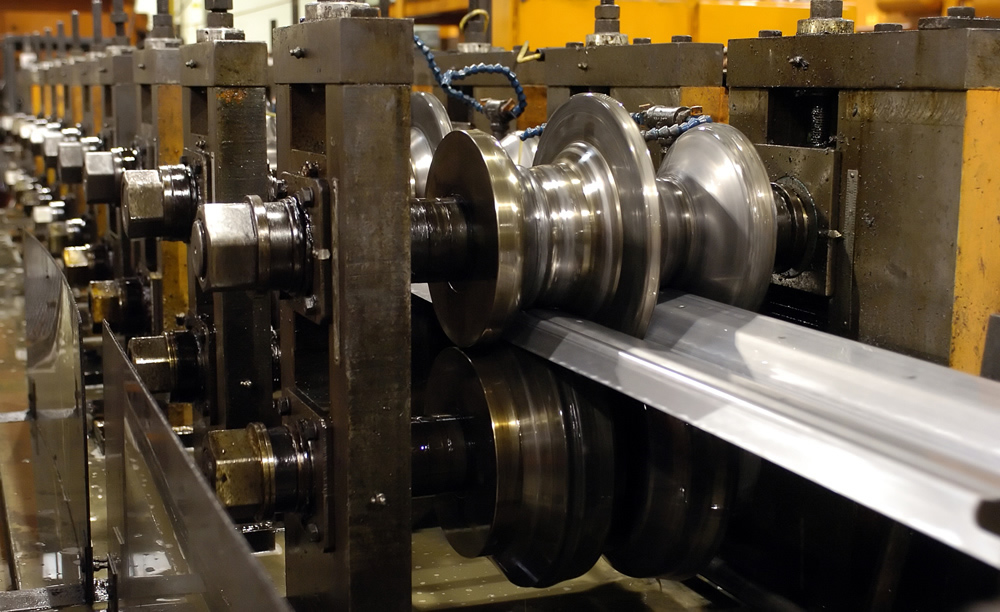

Roll Forming as a Bending Process in Metal Fabrication

Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications. Unlike most forming operations, which have various combinations of forming. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Any time the sheet metal is changed on a roll forming line, it.

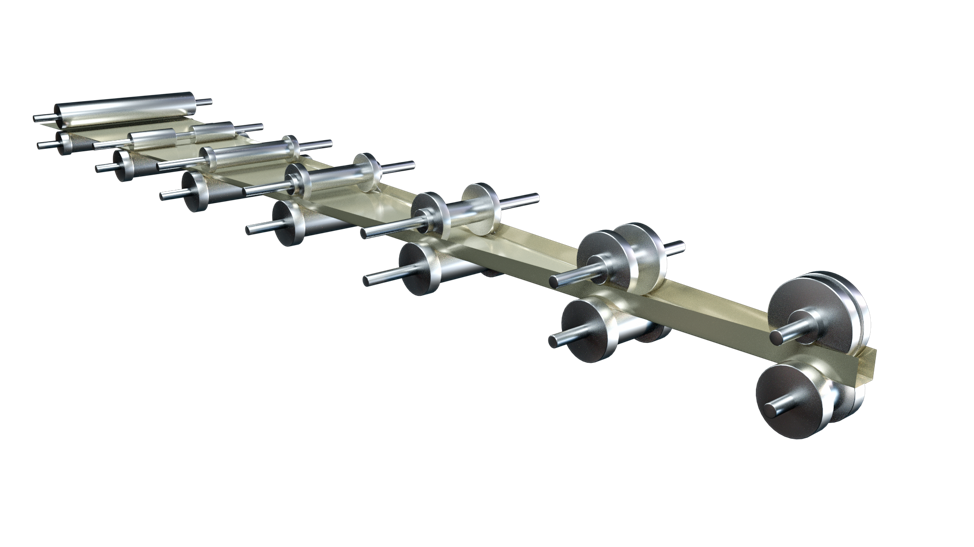

What is Roll Forming? National Material Company Steel Processing

Any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Unlike most.

Roll Forming Sheet Metal Fabrication Yarder Manufacturing

The forming on a roll former occurs as the sheet metal rolls under. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications. Unlike most forming operations, which have various combinations of forming..

Roll forming YouTube

The forming on a roll former occurs as the sheet metal rolls under. Unlike most forming operations, which have various combinations of forming. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications..

What is Roll Forming? National Material Company Steel Processing

Unlike most forming operations, which have various combinations of forming. The forming on a roll former occurs as the sheet metal rolls under. Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Any time the sheet metal is changed on a roll forming line, it is carried out by the roll.

Sheet Metal Roll Forming Roll Forming The Ultimate Guide 2021

Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Unlike most forming operations, which have various combinations of forming. Any time the sheet metal is changed on a roll forming line, it is carried out by the roll former’s tooling. The forming on a roll former occurs as the sheet metal.

Any Time The Sheet Metal Is Changed On A Roll Forming Line, It Is Carried Out By The Roll Former’s Tooling.

Roll forming is one of the few sheet metal forming processes requiring only one primary mode of deformation. Explore metalforming, llc's advanced metal roll forming systems and rollformers, designed for efficiency and precision in sheet metalworking applications. The forming on a roll former occurs as the sheet metal rolls under. Unlike most forming operations, which have various combinations of forming.