Malleable Sheet Metal - Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. This property isn’t seen in non. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking.

This property isn’t seen in non. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking.

This property isn’t seen in non. Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking.

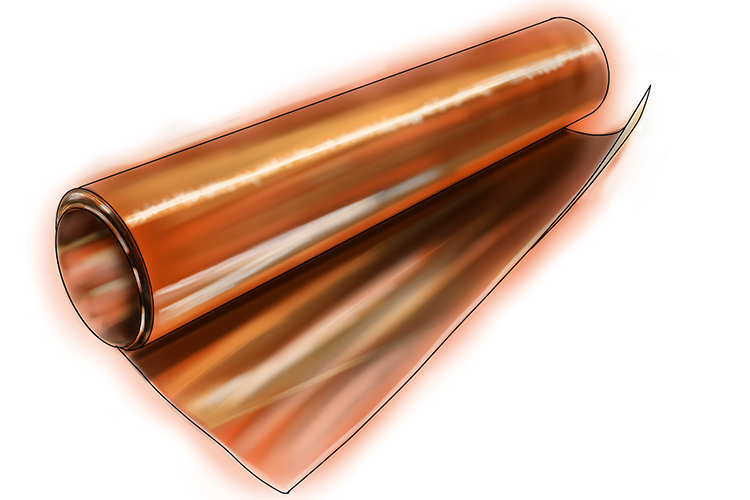

Examples of malleable materials are aluminum foil, lead, white gold

This property isn’t seen in non. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming.

Malleability in Metals Shaping Applications and Versatility

Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. This property isn’t seen in non. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming.

What are the Most Malleable Metals? Metal Supermarkets UK

This property isn’t seen in non. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling.

Difference Between Ductility and Malleability

Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. This property isn’t seen in non. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling.

What Is the Most Malleable Metal

Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. This property isn’t seen in non. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling.

Very Durable Malleable And Ductile Stainless Steel Sheet Use For

Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. This property isn’t seen in non. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling.

PPT 4.4 Metallic bonding PowerPoint Presentation ID400526

Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. This property isn’t seen in non. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling.

What is the Melting Point of Aluminum? WorldAtlas

This property isn’t seen in non. Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking.

Metals are often shiny malleable and very good at conducting

Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. This property isn’t seen in non. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming.

Malleable metals hires stock photography and images Alamy

Malleability is especially important in manufacturing operations like forging, extrusion, and sheet metal forming. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking. Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. This property isn’t seen in non.

Malleability Is Especially Important In Manufacturing Operations Like Forging, Extrusion, And Sheet Metal Forming.

Malleability is commonly characterized by a material’s ability to create a skinny sheet by blow or rolling. This property isn’t seen in non. Malleability is a physical property of materials that allows them to be deformed under compressive stress without breaking.